PNEUMATIC SWING TYPE SPRUE PICKERS

Sprue pickers are labor-saving robots utilized to quickly remove sprues and molded parts from a plastic injection molding machine. Our pneumatic sprue pickers ensure quick and consistent sprue/part removal with the newly designed rigid body and dual shock absorbing system.

FEATURES

- Newly designed body: The controller unit (controller and air valves) are built into the solid main body and he components are well-laid out to be insulated from the influence of surroundings.

- Easy to reach: The “single-action” feature with the easy-to-reach ratchet position, provides smooth and speedy mold change-over.

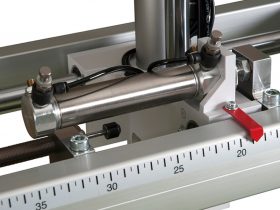

- Ball bushing on the side pipe slide: Combining the sliding unit and the cylinder terminal increases the durability and reduces vibration.

- Fixing with set screws: employing the set screws makes it easy to lock the wrist rotation unit when it is not in use.

- The wirings are tucked into the wrist unit to avoid unnecessary contact or breakage of the wirings.

- DUS system* equipped

- Wider diameter: Changing the cylinder bore diameter from φ25 to φ32

reduces the take-out time up to 20% (comparison with our previous model) - Thciker shaft on the kick unit: Enforcing the stability of the rotational shaft and reducing the vibration

What is the *DUS system?

This system employs double cushioning on the main arm (shock absorber + neumatic cushioning) to reduce the stress and increase the durability on the shock absorber by adjusting the timer of the pneumatic cushioning according to the length of the vertical stroke.