3-AXIS AND 5-AXIS TRAVERSE ROBOTS FOR LARGER IMM

Our 3-axis and 5-axis servo traverse robots are used for various applications in the horizontal plastic injection molding processes that require high-speed unloading of molded parts.

The HRXIII-550i, 800i, and 1000i models are designed for larger IMM and have a 400-1,300t payload capacity.

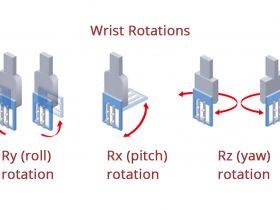

There are two types of 2-axis servo wrist model (Ry or Rz) to select from for your production needs; parts releasing pattern or integration with other automation machines.

The Ry wrist model is capable of rotating around the y (“roll”) and x (“pitch”) axis while the Rz model for the z (“yaw”) and x (“pitch”) coordinates (see images in the gallery).

- Applicable Robots: HRXⅢ-i & b Series (100i/b-850i/b)

- Horizontal, vertical, and rotational motions are servo controlled to drastically increase efficiency in removal of special-shaped parts, undercut, and transfer to a downstream camera station, a box filling system, or a degater.

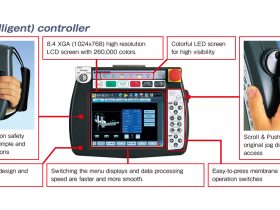

FEATURES

The ideally designed HRX III series contributes to improving productivity in factories, generating faster take-out time and a wider range of the maximum payload.

STANDARD

- Vacuum ejector : 1 circuit

- Palletizing (up to 999 points per axis)

- Selectable home positions (1st Entry / Out-Mold / Above Mold / Backward)

- Reject circuit

- Counters (Example: Initial Reject / Sampling)

- Pass motion (speedup motion)

- Part grip : 1 circuit

- Built-in memory for mold data

(up to 1000 memories) - Smart Programming

- Initial reject

- Take out from moving platen

- Display language selector

- Main Sprue Grip: 1 circuit

- Adjustable point coordinates during the auto-run

- Customizable screen display layout

- Sampling

- Wrist flip en-route (speedup motion)

- Quick point-teaching features (Teach & Go / Point Stop / Cordinates entry)